Society for Industrial Archaeology (SIA)

Southern Chapter Field Trip, April 24, 2010

The Chapter took a field trip to Historic Machinery Services, Inc.

Our host for this trip was member Bob Yuill, who is the proprietor of Historic Machinery Services Corporation (HMS), located in Steele, AL. For more information about Bob's company, you may visit their website http://www.historicmachineryservices.com/ .

HMS is in the business of restoring machinery and Bob is one of a handful of private companies in the United States qualified to restore steam locomotive boilers. Thus, his business is a fine machine shop located in a single large metal building. Most of the shop is "open" with a small office and storage area as well as a "mezzanine" storage area above the shop floor. On the day of our visit, Bob had 3 locomotive boilers in the shop as works-in-progress.

If you ever wanted to understand how a steam locomotive boiler works, then this is the place and Bob is the man to tell you.

|

|

| This is the general view of the inside of Bob's shop. The boilers are stripped to bare bones. | Bob's able assistant Jason (left) explains a process to visitor from Nashville, Nicho Young. Although relatively young, Jason has a lot of experience around the country doing this specialized work. |

|

|

| Bob in the tool crib showing how many different air hammers are used work work on the boilers. |

Bob explains the work being done to this boilers firebox area. Note our young visitor, Jim Lowery's grandson, Jax Hendrick, getting the "bug" at an early age with grandfather. Our oldest member, Thurman Robertson is in the hat -- and the age difference is about 80 years! |

|

|

|

Bob explains that not all parts can be ordered "from- the- catalogue" and so must be fabricated in the machine shop. |

"Young" Marty Schulman explaining the finer points of stay bolts to our young visitor. |

|

|

|

|

One of the first things to do on a "new" project is to determine the plate thickness on a one foot grid. This indicates need for replacement or indicates the limit of future loads (pressure) that may be applied to the boiler. The chalk marks are plate thickness in decimal inches. |

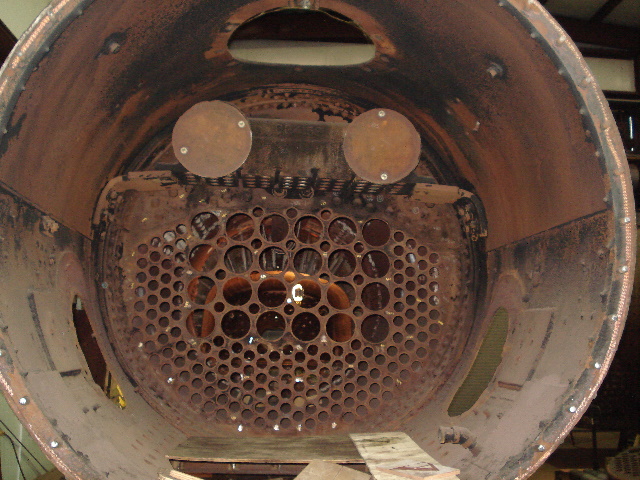

The inside of the boiler, ahead of the firebox includes the steam pipe, braces and the space for the boiler tubes. This is the part of the boiler where heat from the firebox is exchanged to heat the water that surrounds the tubes. When the water boils, the steam rises to the top of this section of the boiler, collects at the highest point in the steam dome and passes through the throttle valve and through the "dry pipe" toward the front of the boiler and the cylinders. Here the tubes are removed, but you may see the location that they occupy by the holes in the plate at the far end of the picture. The large pipe top center is the steam "dry" pipe which delivers steam from the top of the steam dome, forward passing through the smokebox space (but separate from it) where the steam pipe divides to go to the cylinders. |

|

|

|

This is view from the front of the boiler, in the smokebox area. The two circles at the top are the steam pipes (now bifurcated) which will pass down and to the sides on the way to the cylinders. The boiler tubes would open into the smokebox area (imagine pipes through each hole you see). The hot gases from the firebox would then discharge into the smokebox area, having had their chance to exchange heat with the water surrounding them in the previous section. The opening at the top is for the smokestack. The hot gases from the firebox, aided by spent steam from the cylinders passes out the stack. The gases make the smoke, and the spent steam makes the "chuff" or if you must, the "choo-choo"! The steam is used to help force a draft for the firebox. |

Here is a pair of legs standing inside the firebox, at the rear of the boiler, in front of the cab. All the "bumps" that you see are staybolts -- these hold the two walls, inner and outer, of the firebox in place. So there is actually a space all around the firebox, closed on the bottom, and filled with water. Heat from the firebox is transferred here as well, and steam in this outside space is collected and used as well. |

|

|

|

This is a view looking up into the space maintained by the staybolts. This area would be full of water and MUST be maintained to a minimum water level. Failure to do so would result in burning out the "crown sheets" and a boiler explosion with deadly results. |

One of the common ailments Bob repairs is the corrosion of the "mud sill" at the bottom perimeter of the fire box. Old boilers collect scale and rust (much like your home water heater) and often the lower part of the firebox must be replaced. This heavy bar stock is being prepared to build a new mud sill, with deep full penetration butt welding. |

|

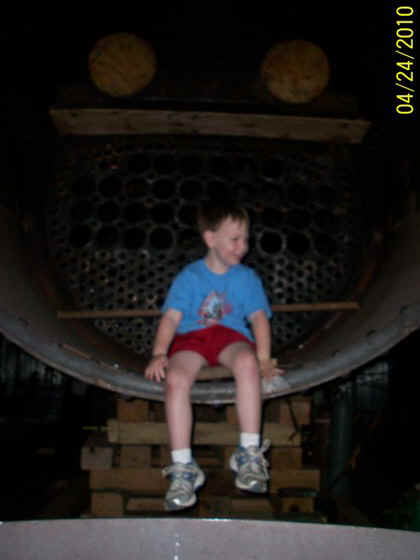

If you wanted to learn about unique machine repair and boilers this was a great field trip. We appreciate very much Bob Yuill having us for a visit. The other part of the visit included reviewing the APT film of the moving of Frisco 4018 from Fair Park to Sloss Furnace in Birmingham. Bob Yuill worked as a consultant for loading and rigging and John Stewart coordinated the rail move with CSX. If you want to know if we have fun on our field trips just ask Jax Hendricks! Jax is the grandson of Jim Lowery and he had a great time, shown here sitting in the smokebox. |

|

If you are interested in joining the Southern Chapter of the SIA, and working to learn about industrial history of the Birmingham District, please contact the Chapter through this website. Email regarding Southern Chapter SIA